What is screw cam-out?

It is said that the tip of the tool lifts when the tool is pressed against the screw and the screw is turned.

Cam-out is the cause of screw stripping.

If you strip it, the workability will be impaired and it will be difficult to tighten or remove the screw.

To remove the stripped screws, you need to drill holes with the screws or break parts of the product.

In order to protect the product, it is important to use screws that are difficult to come out.

Two types of screws with a structure that is difficult to cam-out

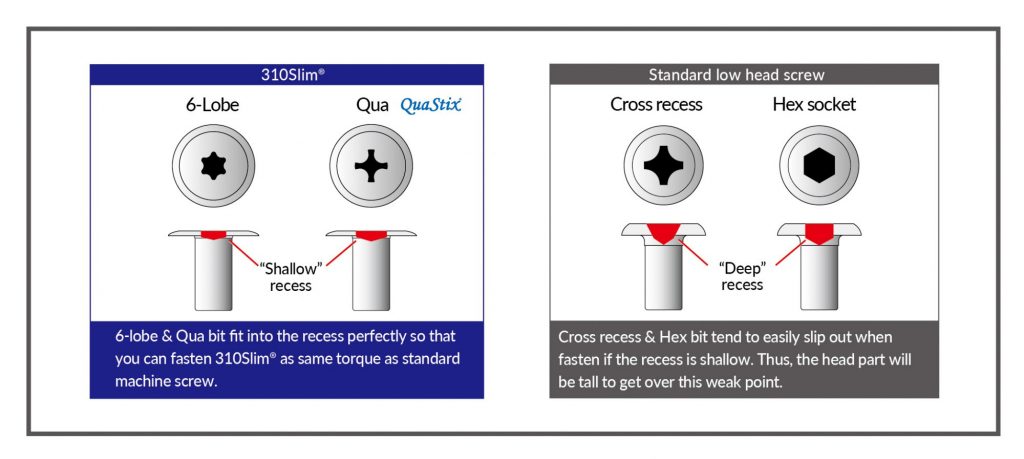

The 310Slim® uses 6-lobe (star-shaped) and quo (cross-hole type) head shapes that are difficult to come out.

Since it is an ultra-low head, it is a screw that is difficult to come out even though it has a shape with little protrusion.

Screws that are hard to cam-out

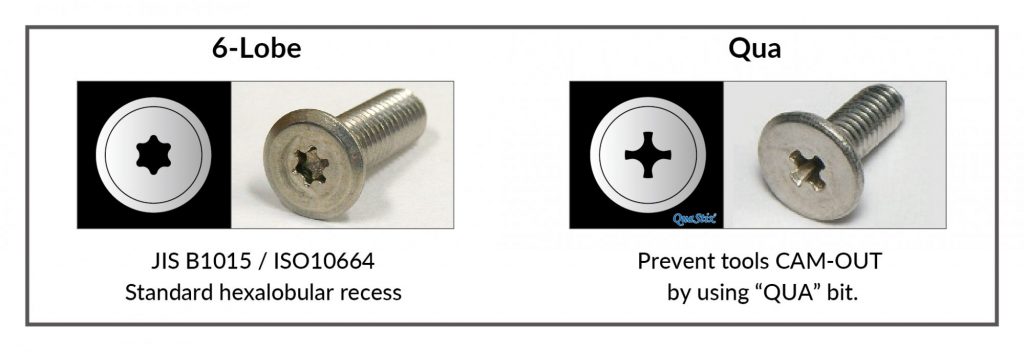

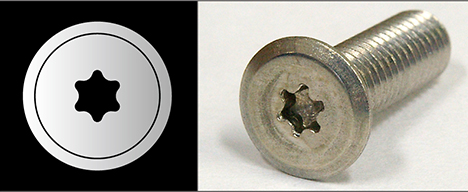

6-Lobe is a “JIS B 1015” hexarobula shape.

It is less likely to cam-out than a cross hole or a hexagon hole, and has a shape with better torque transmission.

The tool is the same as the cross hole and hexagon hole, so it is available anywhere such as home centers and the web because it is JIS standard

Of course, it can be purchased at Saima’s web shop.

QUA(Cross Hole)

The 310 Slim ® is also available in a QUA (cross hole) type, and can be used with commercially available cross screwdrivers and bits.

In addition, by using a special tool, it is more difficult to cam-out.

Why doesn’t it come out even though it’s a cross-hole type?

Compared to normal cross holes, the QUA (cross) has a structure that is difficult to come out because it adheres to the bit better and there is no exit slope.

Good bite with bits and excellent workability.

The QUA (cross hole) has a structure that is difficult to come out, and it is a screw that has good bite with the bit and has excellent workability.

It can also be expected to improve work efficiency.

“6-Lobe” and “QUA” Torque transmission is good

The 310Slim ® uses “6-Lobe” and “QUA” for the recess (hole) in order to reduce the head height to the extreme. Both recesses have good torque transfer, allowing the fastening tool to hook securely even in shallow holes and fastening at the same standard tightening torque as machine screws.

Tips for not caming-out

Tips for not caming-out

It is important to press the tool against the screw when tightening the screw and turn it under load so that the tip does not lift.

※It is generally said that 7 (pushing force): 3 (turning force)

Do not tilt the tool

If the tool is pressed at an angle, the direction of the force will shift and it will cause it to float.

It is important to apply it straight to the screw.

Use the right tool size

If the tool size is different, it will be easier to come out.

If you cam-out and lick the head of the screw

You will not be able to tighten the screws, and it will be difficult to remove them.

It takes a lot of time just to deal with the stripped screws.

Improved efficiency with hard-to-cam-out screws

Stripped screws can take a long time to deal with.

By using screws that are difficult to come out, you can eliminate the time to deal with them and improve efficiency.